Head, Mechanical Engineering Department

B.E., M.E., Ph.D.

+91 94239 68952

hod.mechanical@tgpcet.com

I take this opportunity to welcome you to the department of Mechanical Engineering which was established in 2011.Our graduates work in the core area such as mining industry, thermal power industry, automobile industry, agricultural sector, shipping industries, aerospace industry and finds its utilities in IT sector for Research and Development activities to meet requirements of present industrial needs.

The primary focus is to impart quality technical educations through effective Teaching Learning process among students .The department having three sponsored Lab 3D Printing, BMW Engine Lab and CNC Lab which is obliging for the superior placement of students as per their domain wise interest. Young, dynamic and experienced faculties provide technical knowledge and facilitate the growth of students. The faculty members display a high level of dedication and enthusiasm towards both teaching and state-of-the-art research.

Department is also having 15 well equipped laboratories including a project laboratory and an Industry sponsored laboratories and research laboratory. Our faculty members have published their research articles in reputed national and international journals. The department is active in organizing the various workshops and seminars for the growth and development of faculty and students. Our department students are also highly encouraged to implement their innovative research ideas with the help of the expert faculty members.

Establishment in the year : 2011-12

Current Intake : 120

NAAC Accreditation Status : Yes

Department of Mechanical Engineering was established in 2011 and a B.Tech degree course Mechanical Engineering started with an intake of 60 with the objective of imparting quality educationin the field of Mechanical Engineering. The Department is NBA Accredited from session 2023-24

The focus of the department is towards research and training activity based on advanced manufacturing processes and production, in the field of mechanical designing software, computational fluid dynamics,etc.

The Department has its own departmental Library with a rich collection of books to serve as a ready source of information. With a team of experienced & well-qualified faculty members, the department moulds its students according to the present industrial requirements in various domains such as production, material science, design, ergonomics, so as to provide better employment opportunities. The department of Mechanical Engineering in TGPCET possesses a faculty team of experienced & well-qualified professors, well acquainted with deep subject knowledge, commitment to disseminate quality & value-based education in technical subjects. All faculties work hard on student to meet the requirement of market and groom the student to be job friendly.

The Department imparts high class training & research, providing state of the art practical knowledge to the students.

It also promotes active industry-institute collaboration by identifying areas of interest and taking part in sponsored research projects, organizing workshops, STTP’s and involving in live projects.

To achieve above objects our designed program requires each student to undergo industrial training at the end of 6th Sem. The students carry out mini projects, dissertations during the Pre-Final Year, and undertake a 6-month project during the Final Year. To add value to the program, the department organizes industrial visits and expert lectures on emerging trends by eminent personalities from industry and academia.

The Department gives an exposure for Consultancy works. The department guides to the students for post graduate (GATE, CAT) entrance exam and various public sector examinations by means of special coaching and expert lectures.

Beyond the regular academic classes and activities, the department also is active in: -

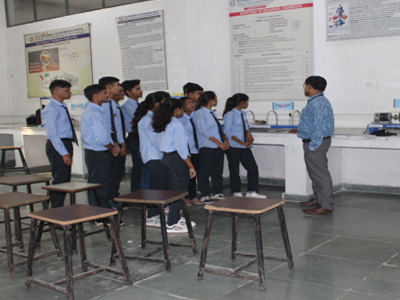

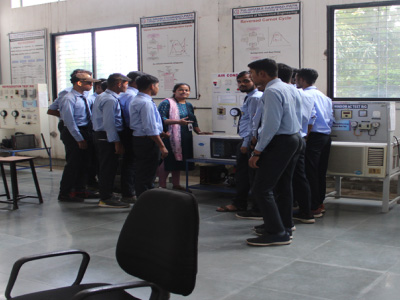

The Department has well-established laboratories in subjects of Heat Transfer, Mechanical Measurement and Metrology, Computer Aided Analysis and Design, Machine Drawing lab, Engineering Metallurgy, Refrigeration and air Conditioning Lab, Energy conversion, I.C Engine Lab, Mechatronics Lab, Automation in Production Lab, Dynamics of machine, Work Shop. The department also maintains a well-equipped audio - visual room, wall-charts demonstrating various Mechanical Engineering theories and techniques. It also has an e-library & e-journals for references.

| Sr. No. | Name of Faculty | Qualification | Designation | Date of Joining |

|---|---|---|---|---|

| Prof. Ritesh Banpurkar | M.Tech (MED) Ph.D* | Asst. Prof. | 06-Aug-13 | |

| Dr. Neerajkumar Wayzode | M.E. (CAD/CAM), Ph.D (ME) | Asst. Prof. | 17-Jul-25 | |

| Prof. Ravindra Shende | M.Tech (TE), Ph.D* | Asst. Prof. | 30-Dec-16 | |

| Prof. Vivek Patil | M.Tech (MED) | Asst. Prof. | 19-Jul-17 | |

| Prof. Praful Randive | M.Tech (CAD/CAM), Ph.D* | Asst. Prof. | 19-Jul-17 | |

| Prof. Gaurav Nagdive | M.Tech (HPE), Ph.D* | Asst. Prof. | 15-Dec-15 | |

| Dr. Vinay Kumar | M.Tech ( MD) Ph. D (ME) | Asst. Prof. | 02-Aug-23 | |

| Prof. Abhijit Misal | M.Tech ( MED) | Asst. Prof. | 05-Jan-24 | |

| Prof. Kunal Meshram | B.E. (ME) M.Tech (CAD/CAM) MBA ,Ph. D * (ME) | Asst. Prof. | 02-May-25 | |

| Prof. Sachin Goswami | B.E. (ME), M.Tech (MED) | Asst. Prof. | 02-May-25 | |

| Dr. Deepak Kumar Paswan | B.tech (ME), M.Tech (Fuel Engg.), Ph.D (Fuel Engg.) | Asst. Prof. | 18-Jun-25 | |

| Dr. Satyendra Kumar | B.Tech (ME) , M.E (ME), Ph.D (ME) | Asst. Prof. | 08-Jul-25 | |

| Dr. Udai Chandra Jha | M.Tech , Ph.D (ME) | Professor | 08-Sep-25 | |

| Dr. Durwesh Jhodkar | M.E. (ME), Ph.D (ME) 2019 | Asso. Prof. | 15-Sep-25 | |

| Dr. Prashant Kadu | B.E. (ME), M.Tech (MED), Ph.D (ME) | Professor | 16-Jun-25 |

"To emerge as a premier centre in the field of Mechanical Engineering Education and produce competent Engineers."

To impart quality Technical Education through effective teaching -learning process.

To provide a better environment to encourage innovation and entrepreneurship.

To strengthen industry institute interaction to meet the challenges of industry and society.

To ensure overall development of students and staff members by inculcating knowledge and professional ethics.

Graduates will be able to

PEO1 : Demonstrate essential technical skills to identify, analyze and solve problems and design issues in mechanical engineering.

PEO2 : Analyze the complex problems in the field of mechanical engineering by using modern tools.

PEO3 : Apply mechanical engineering concepts for the betterment of society and environment.

PEO4 : Develop professionals having administrative and managerial skills for mechanical engineering and allied industries.

PEO5 : Demonstrate the attributes of mechanical engineering in lifelong learning to contribute towards societal needs.

Graduates will be able to

PSO 1: Apply the knowledge to work professionally and ethically in Thermal, Design, production and Manufacturing areas of Mechanical engineering.

PSO 2: Analyze and design mechanical components and its processes to meet the societal needs.

PSO 3: Apply Engineering and Management principles to work professionally in the industry or as an entrepreneur.

Engineering Graduates will be able to:

The class room details are given in table

| Sr. No | Infrastructure | Quantity |

|---|---|---|

| 1 | Smart Class room | 01 |

| 2 | Class room | 06 |

| 3 | Tutorial | 01 |

| 4 | Seminar Hall | 01 |

Heat Transfer Lab

Mechanical Workshop

Dynamic of Machine Lab

Hydraulic Machine Lab

Refrigeration and Air conditioning lab

CAD Lab

Internal Combustion Engine Lab

Mechatronics Lab

Automobile Engineering Lab

CNC & Robotic Lab

BMW Engine Lab

Seminar Hall

Smart Class Room

| Sr. No | Title of Activity |

Date of Activity |

Name of Resource Person |

Designation and Affiliation of Resource Person |

Name of Professional Society (under which activity is conducted) |

No. of Students Benefited |

Relevance to POs, PSOs |

|---|---|---|---|---|---|---|---|

Intellectual Property Rights (IPR) & Patent, Designs filing |

05/08/2024 |

Dr. Bharat Suryawanshi |

Asst. Controller of Patents and Design, Nagpur |

IEI & ISTE |

82% |

PO1, PO5, PO8, PO9 and PO12. |

|

An overview on Industry 4.0 & Its Applications |

07/08/2024 |

Dr. Ritesh Jain |

Manager, Service Engineering Department, at Mahindra & Mahindra Ltd (Farm Division), Hingana |

IEI & ISTE |

84% |

PO 1, PO 2 |

|

| Expert Lecture on Green Sand Casting Process and Its application in Automotive Industry | 18/08/2023 | Dr. Sanjay Aloni | Assi. General manager marketing and technical, Goyal Technochem Pvt ltd, Nagpur | ISTE | 80% | PO1,02 ,05,10, 12, PSO 01,02,03 | |

| Hands on training on BMW engine | 28/07/2023 to 29/07/2023 | Mr. Bishnu Dutt Darnal | Senior Manger Training, Mahindra and Mahindra, Farm Division, Nagpur | ISTE | 80% | PO1,02,03,04,05, 12, PSO 01,02,03 | |

| One week FDP on 3D printing and its Application in Industry 4.0 | 16/5/2023 to 20/05/2023 |

1.Dr.Rakesh Mote 2.Dr.Nitin Kumar Lautre 3.Dr.G.K.Awari 4.Dr. S.W.Rajurkar, 5. Dr.I.A. Palani 6. Mr.Murtaza Cochinwala 7. Dr.Abhijit Digalwar |

1. Asso.Professor, IIT Bombay 2. Asso.Prof. VNIT,Nagpur 3. Prof. and Head, Gov.Poly. Nagpur 4. Asso.Prof. Gov.College of Engineering, Chandrapur 5. Prof. IIT, Indore 6. Director, IID, Nagpur 7. Prof. and research Head, Symboisis International Pune, Nagpur Campus |

ISTE | |||

| Awareness on Automotive Engineering | 21/07/2023 | Mr.Vivek Shrouty | General manager(Customer Service) Evonith Value stell ltd. Wardha |

ISTE | 85% | PO1,02 ,06,07, 8,12, PSO 01,02,03 | |

| Guest Lecture on Industry 4.0 | 29/08/2022 | Dr.D.A.Zole, | Asso.Professor, Mechanical Engineering Department, VNIT, Nagpur | ISTE | 70% | PO1,02,05, ,12, PSO 01,02,03 | |

| Guest Lecture on Energy Conservation in day to day life | 07/01/2022 | Mr.Pramod Nichat, | Asst. General manager (Retd.) Ashok Layland ltd. And PCRA Member, Nagpur |

ISTE | 75% | PO1,02,05, ,12, PSO 01,02,03 | |

| Expert Lecture on the essence of Industrial robotics and automation and opportunities for graduates | 01/12/2022 | Mr.Anil Tatode, | Traning Officer , Department of Robotics and Cloud Technology, RTMNU Nagpur | ISTE | 78% | PO1,10,11,12 PSO 01,02,03 | |

| Expert Lecture on Intellectual Property Right and Patent Information System | 03/04/23 | Mrs. ChhayaSatpute, | Rajiv Gandhi National Institute of Intellectual Property Management, Nagpur | ISTE | 70% | PO8,09,10,12, PSO 03 | |

| Industry Expectation from Young Engineers | 30/05/2023 | Mr. Manish Shahane, | Sr.Officer, KEC Training Centre, Buttibori, Nagpur | ISTE | 75% | PO1,02,05,08,12, PSO 01,02,03 | |

| Guest Lecture on Maximum Opportunities for future Job | 01/06/2023 | Mr.Mayur Dongare | State Manager- Maharashtra and Goa. AIR Vision Infinity Pvt.Ltd | ISTE | 76% | PO1,02,05,08,12, PSO 01,02,03 | |

| Khosla Engineering Industries” Hingna,Nagpur | 07-10-2022 | Mr. Pradip Singh | Sr. Engineer, Khosla Engineering Industries” Hingna,Nagpur | ISTE | 56 | PO1,2,3,4,5,6,9,10,11,12,PSO1,2 | |

| Incubation Center of Shri Ramdeobaba College of Engineering and Management Nagpur | 09-03-2023 | Dr. Y.M. Sonkhaskar, | RCOEM-TATA CIIIT Centre, Nagpur | ISTE | 48 | PO1,2,3,4,5,6,9,10,11,12,PSO1,2 | |

| Br.Sheshrao Wankhede Shetkari Sahakari Soot Girni Ltd.Mohagaon Butibori | 27-03-2023 | Mr.Wadekar, Manager |

Br. Sheshrao Wankhede Shetkari Sootgirni Ltd , Nagpur | ISTE | 60 | PO1,2,3,4,5,6,9,10,11,12,PSO1,2 | |

| Shilpa Steel Industries Ltd. Butibori | 13-04-2023 | Mr.Praksh Borkar, | HR, Manager Shilpa Steel Industries Ltd, MIDC Buttibori Nagpur |

ISTE | 50 | PO1,2,3,4,5,6,9,10,11,12,PSO1,2 | |

| Lokmat PrintingPress , Industrial Area Butibori | 05-05-2023 | Mr.Bhushan Chandankhede, |

Lokmat PrintingPress , Industrial Area Butibori | ISTE | 45 | PO1,2,3,4,5,6,9,10,11,12,PSO1,2 | |

| Adani Power Plant, Tiroda, Gomdia | 17-07-2023 | Mr.Bhushan Chandankhede, |

Field En gineers”Adani Power Plant, Tirora MIDC | ISTE | 55 | PO1,2,3,4,5,6,9,10,11,12,PSO1,2 | |

| Guest Lecture on strategic innovation and new product introduction (NPI) | 16/03/2022 | Mr. Manish Hatwar | Director Project Management GE Renewable energy Germany |

ISTE | 75% | PO1,02,03,05,06,10,12, PSO 01,02,03 | |

| Expert Lecture on industrial robotics and automation and opportunity for graduates | 16/03/2022 | Mr. Anil Tatode, | Department of Robotics and cloud technology RTMNU Nagpur | ISTE | 70% | PO1,02,03,04,05,10,12, PSO 01,02 | |

| Expert Lecture on Management techniques of Chhatrapati Shivaji Maharaj | 19/02/2022 | Dr. Amol O. Pusadkar | ISTE | 80% | PO6,07,08,0911, PSO3 |

||

| Expert Lecture on Solar Energy: Indian Scenario | 30/09/2021 | Dr. Ravindra Babu Yarasu, | Associate Professor, Government engineering college Nagpur | ISTE | 90% | PO1,02,03,04,05,06,07,10,12, PSO 01,02 | |

| Webinar on Coal to Electricity | 19/09/2021 | Dr. Vijay Gandhewar, | Technical Training Head and HR, Adani Power Maharashtra Ltd. Tiroda | ISTE | 90% | PO1,02,03,04,05,06,07,10,12, PSO 01,02,03 | |

| Intellectual Property Right and Patent Information System | 11/09/2021 | Mrs. Chhaya Satpute, Rajiv |

Gandhi National Institute of Intellectual Property Management, Nagpur | ISTE | 75% | PO8,09,10,12, PSO 03 | |

| Expert Lecture on Non Destructive Testing and its Application | 13/09/2021 | Mr. Vatan Ukey, | Director Aruna Engineering and Inspection services, Nagpur | ISTE | 70% | PO1,02,03,04,05,06,07,10,12, PSO 01,02,03 | |

| Expert Lecture on Mechanical, Thermal and Electro-technical Calibration | 20/04/2022 | Mr. Anil Chaoudhari, | Technical manager, ACME Enterprises, Nagpur | ISTE | 80% | PO1,02,03,04,05,06,07,10,12, PSO 01,02,03 | |

| Ador Fontech Limited, MIDC Hingna, Nagpur | 11/04/2022 | Mr. Mahesh Gonjare. | Hr Manager, Ador Fontech Limited, MIDC Hingna, Nagpur | ISTE | 65 | PO1,2,3,4,5,6,9,10,11,12,PSO1,2 | |

| Br. Sheshrao Wankhede Shetkari Soot Girni Ltd , Nagpur | 21/04/2022 | Mr. Pawan Dadwe, | Shift Production Incharge,, Br. SheshraoWankhedeShetkari Soot GirniLtd , Nagpur | ISTE | 72 | PO1,2,3,4,5,6,9,10,11,12,PSO1,2 | |

| Oberoi Centre Of Excellence For Robotics , Robotics department labs, University Campas | 28/04/2022 | Mr.Mahesh Yelkar, | Programme head, Oberoi Centre Of Excellence For Robotics , Robotics department labs, University Campas | ISTE | 68 | PO1,2,3,4,5,6,9,10,11,12,PSO1,2 | |

| Guest Lecture on Bharat Stage-6 pollution norms and their implementation | 15/07/2020 | Mr. Pramod Nichat, | Managing Director, Nichat Human Resource Solutions, Nagpur | ISTE | 75% | PO1,02,03,04,05,06,07,10,12, PSO 01,02,03 | |

| Guest Lecture on Galvanized Process in Steel Industry | 30/08/2020 | Mr. Vivek Shrouty, | Dy. General Manager Uttam Galva Metallics Limited, wardha | ISTE | 70% | PO1,02,03,04,05,06,07,10,12, PSO 01,02,03 | |

| Guest Lecture on Lean six sigma Methodology to increase Quality | 10/06/2021 | Mr. Mayur Chapate, | Sr.Manager, Reliance Industries and Consultant NIQC, International Banglore | ISTE | 80% | PO1,02,03,04,05,06,07,10,12, PSO 01,02,03 | |

| Guest Lecture on Bearing Technology | 14/06/2021 | Mr. Dhirendra Gotmare, . |

Manager Sales- Industry Scheffler India Ltd |

ISTE | 78% | PO1,02,03,04,05,06,07,10,12, PSO 01,02,03 | |

| Guest Lecture on Entrepreneurship and Entrepreneurial Development |

31/08/ 2020 | Mr. Mukesh Adhar, | Co-founder, Lemon LSE & JCE, USA Certified Trainer. |

ISTE | 75% | PO 08,09,10, 11,12 , PSO 03 |

|

| E-International Conference on Artificial Intelligence and Machine Learning-20 | 27 to 28/11/ 2020 | Dr. Rupesh Patil, | Principal, Navsahyadri College of Engineering, Pune |

ISTE | 85% | PO1,02,03,04,05,06,07,08,09,10,12, PSO 01,02,03 | |

| SANY Mega Excavator Manufacturing Industry | 27/04/2021 | Mr.Vishwjeet Ambade | Asst.Prof. Mech Dept. (TGPCET,Nagpur) | ISTE | 67 | PO1,2,3,4,5,6,9,10,11,12,PSO1,2 | |

| Pirelli Settimo Torinese Factory (Tyre Manufacturing Company) | 28/04/2021 | Mr.Vijay Talodhikar | Asst.Prof. Mech Dept. (TGPCET,Nagpur) | ISTE | 89 | PO1,2,3,4,5,6,9,10,11,12,PSO1,2 | |

| Guest Lecture on Employability and Skill Enhancement | 08/02/2020 | Mr. Prashant Dighe | HR & IR Manager Morarji Textiles Ltd., Nagpur |

ISTE | 65% | PO 08, 09, 10, 11,12 , PSO 03 |

|

| Guest Lecture on “Energy Conservation and Fuel Efficient Technologies” Association with PCRA | 29/02/2020 | Mr. Swapnil Thanekar, | Director Petroleum Conservation Research Association |

ISTE | 60% | PO1,02,03,04,05,06,07,10,12, PSO 01,02,03 | |

| Greek Nation | 22/02/2020 |

|

1. Senior Manager Reliance Power Ltd 2. General Manager Reliance Power Ltd |

ISTE | 90% | PO1,02,03,04,05,06,07,08,09,10,12, PSO 01,02,03 | |

| Guest Lecture on Industrial Requirements in Design | 17/01/2020 | Mr. Anubhav Singh |

Group Leader CAD centre, Nagpur |

ISTE | 80% | PO1,02,03,04,05,06,07 10,12, PSO 01,02,03 |

|

| Reliance Power, Buttiboti Nagpur | 01/02/2020 | Ms.Shilpa Gupta & Mr.Vinayak Pradhan, |

Reliance Power, Buttiboti Nagpur | ISTE | 66 | PO1,2,3,4,5,6,9,10,11,12,PSO1,2,3 | |

| Morarji Textile Ltd. MIDC Buttibori Nagpur | 21/01/2020 | Mr. Ashish Dubey & Mr. Jignesh Raut, | Br. Sheshrao wankahde, Shetkari Sahakari sutgirni ltd, Mohagao in Nagpur | ISTE | 90 | PO1,2,3,4,5,6,9,10,11,12,PSO1,2,3 | |

| Ajit bakery Burtibori, Nagpur | 21/01/2020 | Mr. Manish Raman & Mr. Kunal Singh, |

Ajit bakery Burtibori, Nagpur | ISTE | 80 | PO1,2,3,4,5,6,9,10,11,12,PSO1,2,3 | |

| Br. Sheshrao wankahde, Shetkari Sahakari sutgirni ltd, Mohagaoin Nagpur | 17/01/2020 | Mr. Pawan Dadwe, Shift Production Incharge, | Br. Sheshrao wankahde, Shetkari Sahakari sutgirni ltd, Mohagao, Nagpur | ISTE | 90 | PO1,2,3,4,5,6,9,10,11,12, PSO1,2,3 |

| Sr. No | Name of Student | Company Name | Academic Year |

|---|---|---|---|

| Linesh Giradkar | Sanvijay Pvt. Ltd. Buttibori MIDC Nagpur | 2024-25 | |

| Pratik Taiwade | Sanvijay Pvt. Ltd. Buttibori MIDC Nagpur | 2024-25 | |

| Akash Chaudhari | Sanvijay Pvt. Ltd. Buttibori MIDC Nagpur | 2024-25 | |

| Rutvik Dhage | Sanvijay Pvt. Ltd. Buttibori MIDC Nagpur | 2024-25 | |

| Pranay Darne | Sanvijay Pvt. Ltd. Buttibori MIDC Nagpur | 2024-25 | |

| Tanay Singh | Sanvijay Pvt. Ltd. Buttibori MIDC Nagpur | 2024-25 | |

| Suhas Dhone | Sanvijay Pvt. Ltd. Buttibori MIDC Nagpur | 2024-25 | |

| Khumesh Bhagele | Sanvijay Pvt. Ltd. Buttibori MIDC Nagpur | 2024-25 | |

| Aditya Deotare | ADVIK | 2023-24 | |

| Arya Koparkar | ADVIK | 2023-24 | |

| Jyotish Mohatkar | Devgiri Forging Pvt Ltd, Aurangabad | 2023-24 | |

| Kartik Chahande | ADVIK | 2023-24 | |

| Vikky Kosme | Devgiri Forging Pvt Ltd, Aurangabad | 2023-24 | |

| Chetan Chaware | CEAT Limited | 2023-24 | |

| Sameer Kapale | CEAT Limited | 2023-24 | |

| Anklesh Bhoyar | Devgiri Forging Pvt Ltd, Aurangabad | 2023-24 | |

| Devgiri Forging Pvt Ltd, Aurangabad | 2023-24 | ||

| Milind Patle | Devgiri Forging Pvt Ltd, Aurangabad | 2023-24 | |

| Saroj Patle | Devgiri Forging Pvt Ltd, Aurangabad | 2023-24 | |

| Saurabh Pawade | Devgiri Forging Pvt Ltd, Aurangabad | 2023-24 | |

| Tripurai Jaiswal | Devgiri Forging Pvt Ltd, Aurangabad | 2023-24 | |

| Vaibhav Talmale | Devgiri Forging Pvt Ltd, Aurangabad | 2023-24 | |

| Sumit Anil Rinayate | ESAF Small Finance Bank | 2023-24 | |

| Aman Sharma | Pawan Precision | 2023-24 | |

| Prayag Jangale | Rajureshwar Infrastructure Pvt. Ltd. | 2023-24 | |

| Piyush Khadgi | Star Circlips and Engineerining Limited, Nagpur | 2023-24 | |

| Lokesh Sahare | TATA | 2023-24 | |

| Vijay Gaddamwar | TATA Motors Passenger Vehicles Limited | 2023-24 | |

| Akash Dhuldhule | UNO MINDA | 2023-24 | |

| Dikshit Rahangdale | UNO MINDA | 2023-24 | |

| Ganesh Nikhade | Devgiri Forging Pvt Ltd, Aurangabad | 2023-24 | |

| Krushnakant Raut | UNO MINDA | 2023-24 | |

| Rushikesh Wanjari | Devgiri Forging Pvt Ltd, Aurangabad | 2023-24 | |

| Kalyani Vadatkar | Yohesa Financial Services | 2023-24 | |

| Aadil Mohd Asif Katewale | Dhoot | 2022-23 | |

| Aaditya Mangesh Borse | Dhoot | 2022-23 | |

| Abhijeet Ajit Das | Dhoot | 2022-23 | |

| Abhijeet Ramesh Pataliya | Dhoot | 2022-23 | |

| Adarsh Sanjay Rangari | Dhoot | 2022-23 | |

| Akash Diwalu Kumbhare | Varroc Lighting System Limited |

2022-23 | |

| Akshay Shrikrushna Kale | Flash | 2022-23 | |

| Aman Dipak Pachare | Flash | 2022-23 | |

| Aman Krishnamohan Tiwari | Flash | 2022-23 | |

| Amit Sewakram Raut | Flash | 2022-23 | |

| Amol Parasram Jadhav | Flash | 2022-23 | |

| Anand Subhash Ade | Flash | 2022-23 | |

| Aniket Ajay Sukhadeve | Flash | 2022-23 | |

| Aniket Hiramanji Bhagat | Flash | 2022-23 | |

| Aniket Sudhakar Chambhare | Flash | 2022-23 | |

| Anil Ganpat Rathod | Flash | 2022-23 | |

| Ankit Gunwantrao Nimbulkar | Flash | 2022-23 | |

| Ankit Ramesh Patil | Flash | 2022-23 | |

| Ankit Shailendra Singh | Flash | 2022-23 | |

| Anuj Uttam Bhaladhare | Flash | 2022-23 | |

| Bhujang Dhondiba Tharsawde | Dhoot | 2022-23 | |

| Brijesh Prakash Kanhekar | Dhoot | 2022-23 | |

| Chandrkant Vithalrao Talimkar | Dhoot | 2022-23 | |

| Deeksha Mohanrao Chakranarayan | Dhoot | 2022-23 | |

| Dhananjay Maroti Khadse | Dhoot | 2022-23 | |

| Dhiraj Ramesh Shembekar | Dhoot | 2022-23 | |

| Dipak Gomaji Patle | Dhoot | 2022-23 | |

| Dipakkumar Ganuji Baraikar | Dhoot | 2022-23 | |

| Gaurav Laxmanrao Wadhai | Dhoot | 2022-23 | |

| Gayatri Bhujangrao Borkar | Dhoot | 2022-23 | |

| Harsh Manohar Karadbhajne | Flash | 2022-23 | |

| Himanshu Amrut Madai | Flash | 2022-23 | |

| Kaushik Ramesh Bagde | Flash | 2022-23 | |

| Lankesh Laxman Selokar | Flash | 2022-23 | |

| Mahendra Vitthalraoji Mendhe | Flash | 2022-23 | |

| Mahesh Pravin Naukarkar | Flash | 2022-23 | |

| Mrunal Nilkantha Yewale | Flash | 2022-23 | |

| Nandadeep Deepak Dhone | Flash | 2022-23 | |

| Neeraj Sushilkumar Sahare | Flash | 2022-23 | |

| Neha Rajendranath Bachchhere | Flash | 2022-23 | |

| Nikeshkumar Munnalal Pandhare | Flash | 2022-23 | |

| Nikhil Ramdas Wanjari | Flash | 2022-23 | |

| Nikhil Santoshrao Bhambere | Flash | 2022-23 | |

| Nikki Kamalsing Lilhare | Flash | 2022-23 | |

| Nilesh Madan Bawane | Flash | 2022-23 | |

| Nilesh Mohan Kohale | Varroc Lighting System Limited | 2022-23 | |

| Omkareshwar Shankar Dambhare | Flash | 2022-23 | |

| Pradhnyayusagar Bapu Kothari | Varroc Lighting System Limited | 2022-23 | |

| Praful Kishor Raut | Varroc Lighting System Limited | 2022-23 | |

| Pranav Vijay Deshmukh | Varroc Lighting System Limited | 2022-23 | |

| Prashant Jagdish Ladekar | Varroc Lighting System Limited | 2022-23 | |

| Rahul Sudhakar Raut | Flash | 2022-23 | |

| Rohan Vitthalrao Khandare | Flash | 2022-23 | |

| Rohit Nagsen Maskare | Dhoot | 2022-23 | |

| Sachin Devidas Jadhav | Flash | 2022-23 | |

| Samir Divakar Thul | Dhoot | 2022-23 | |

| Sangharsh Madhavrao Powade | Dhoot | 2022-23 | |

| Sanket Kishor Tarak | Dhoot | 2022-23 | |

| Sarvesh Vinayak Pohane | Dhoot | 2022-23 | |

| Shanidev Suresh Tichkule | Varroc Lighting System Limited | 2022-23 | |

| Sushil Nandkishor Malghate | Varroc Lighting System Limited | 2022-23 | |

| Adarsh Mohan Kawale | Flash | 2022-23 | |

| Aditya Madhav Ghodmare | Flash | 2022-23 | |

| Ajaykumar Giridhar Nidwanche | Flash | 2022-23 | |

| Ajit Maheshkumar Lilhare | Flash | 2022-23 | |

| Akshay Dilip Fuke | Varroc | 2022-23 | |

| Akshay Jagannath Chafale | Flash | 2022-23 | |

| Amit Zanklal Patle | Varroc | 2022-23 | |

| Amulya Kumar Das | Flash | 2022-23 | |

| Aniket Shaligram Gayki | Flash | 2022-23 | |

| Aniket Suresh Shende | Flash | 2022-23 | |

| Ashish Anil Ghutke | Dhoot | 2022-23 | |

| Ashish Jitendra Shende | Dhoot | 2022-23 | |

| Banti Kumar Singh | Dhoot | 2022-23 | |

| Bhushan Girijashankar Upadhye | Dhoot | 2022-23 | |

| Chandramani Balaprasad Katkamble | Dhoot | 2022-23 | |

| Chetan Bhimrao Koche | Dhoot | 2022-23 | |

| Dharmaraj Duryodhan Meshram | Dhoot | 2022-23 | |

| Dilip Darasing Lilhare | Dhoot | 2022-23 | |

| Gaurav Vivekanand Thakur | Flash | 2022-23 | |

| Gopal Sanjay Lande | Pure | 2022-23 | |

| Harsha Nandkishor Dongre | Pure | 2022-23 | |

| Hasin Tarachand Deshmukh | Pure | 2022-23 | |

| Hitesh Jagdish Baghele | Varroc | 2022-23 | |

| Jayendra Sukram Hajare | Flash | 2022-23 | |

| Kapil Kamal Nandeshwar | Varroc | 2022-23 | |

| Krunal Suresh Fulzele | Varroc | 2022-23 | |

| Mayur Bhagwat Sananse | Flash | 2022-23 | |

| Mohammed Aqeeb Ur Raheman Taufeeq Ur Raheman | Flash | 2022-23 | |

| Mukesh Radheshyam Rahangdale | Flash | 2022-23 | |

| Nikhil Ramesh Bhivgade | Flash | 2022-23 | |

| Pankaj Gangaram Rahangale | Flash | 2022-23 | |

| Praful Bhagwan Raut | Flash | 2022-23 | |

| Prashant Ramesh Yele | Flash | 2022-23 | |

| Prashik Uttamrao Shelkar | Dhoot | 2022-23 | |

| Rahul Someshwar Bisen | Dhoot | 2022-23 | |

| Rakesh Haribhau Balki | Dhoot | 2022-23 | |

| Ritika Manoj Soitkar | Dhoot | 2022-23 | |

| Rupesh Bhagwan Yerekar | Dhoot | 2022-23 | |

| Sachin Ramesh Ganvir | Dhoot | 2022-23 | |

| Sandip Manoj Kale | Flash | 2022-23 | |

| Santosh Shivlal Bobde | Flash | 2022-23 | |

| Saurabh Ranjan Sahare | Flash | 2022-23 | |

| Shailesh Hanslal Diwewar | Flash | 2022-23 | |

| Suraj Shesherao Surnar | Dhoot | 2022-23 | |

| Vaibhav Bhaurao Chopade | Flash | 2022-23 | |

| Vivek Pradip Deshmukh | Flash | 2022-23 | |

| Achal Siddharth Bambole | Byjus | 2020-21 | |

| Akash Sevaklal Gautam | Argano Pvt. Ltd | 2020-21 | |

| Amit Waman Tikhat | Suntronics Renewable Pvt. Ltd. | 2020-21 | |

| Amol Ramesh Jadhav | WNS Global Services Pvt. Ltd. | 2020-21 | |

| Anchula Sheshrao Punwatkar | Teleperformance Pvt. Ltd. | 2020-21 | |

| Balasaheb Vaijanath Jadhav | Dhoot Transmission Pvt. Ltd. | 2020-21 | |

| Gopal Bhagwan Meshram | Suntronics Renewable Pvt. Ltd. | 2020-21 | |

| Prajwal Pralhad Ramteke | Dhoot Transmission Pvt. Ltd. | 2020-21 | |

| Prakash Kashiram Kakade | Tea Automation | 2020-21 | |

| Pralay Domeshwar Meshram | ALRPS, MIDC, BUTIBORI | 2020-21 | |

| Prem Dilip Dome | Dhoot Transmission Pvt. Ltd. | 2020-21 | |

| Rahul Ramesh Shiwankar | Dhoot Transmission Pvt. Ltd. | 2020-21 | |

| Ritesh Omesh Bhoyar | Dhoot Transmission Pvt. Ltd. | 2020-21 | |

| Shailesh Santosh Sahu | Suntronics Renewable Pvt. Ltd. | 2020-21 | |

| Shubham Mahadeo Gedam | Suntronics Renewable Pvt. Ltd. | 2020-21 | |

| Sushant Tulshiram Giradkar | Dhoot Transmission Pvt. Ltd. | 2020-21 | |

| Vikrant Tryembak Mun | Dhoot Transmission Pvt. Ltd. | 2020-21 | |

| Vinay Dinwar Patle | Dhoot Transmission Pvt. Ltd. | 2020-21 | |

| Abhijeet Ramprasad Mishra | Suntronics Renewable Pvt. Ltd. | 2020-21 | |

| Ajinkya Jeevan Giri | Sailotech Pvt.Ltd. | 2020-21 | |

| Akash Birendra Mukhiya | Shilpa Steel & Power Ltd | 2020-21 | |

| Akash Naresh Bawane | Dhoot Transmission Pvt. Ltd. | 2020-21 | |

| Amol Kishor Raut | Dhoot Transmission Pvt. Ltd. | 2020-21 | |

| Ankushkumar Omkar Yele | Suntronics Renewable Pvt. Ltd. | 2020-21 | |

| Anuradha Nawalkishor Singh | Dhoot Transmission Pvt. Ltd. | 2020-21 | |

| Ashwini Kawdu Satpute | Suntronics Renewable Pvt. Ltd. | 2020-21 | |

| Atharva Sandip Sagdeo | Hindustan Petrolium Corporation Ltd. | 2020-21 | |

| Devendra Rajendra Mude | Dhoot Transmission Pvt. Ltd. | 2020-21 | |

| Dhillon Charanjeet Singh Jagjeet Singh | Jaika Vanijya Pvt. Ltd. | 2020-21 | |

| Gaurav Dilip Kuchankar | Dhoot Transmission Pvt. Ltd. | 2020-21 | |

| Gayatri Arunrao Deshkar | CEAT Limited | 2020-21 | |

| Indrakumar Tukaram Dhawale | Dhoot Transmission Pvt. Ltd. | 2020-21 | |

| Kalyani Kishor Satdeve | CEAT Limited | 2020-21 | |

| Rahul Ravindra Darekar | Dhoot Transmission Pvt. Ltd. | 2020-21 | |

| Pavan Rameshwar Meshram | Dhoot Transmission Pvt. Ltd. | 2020-21 | |

| Pradip Suresh Shelke | Dhoot Transmission Pvt. Ltd. | 2020-21 | |

| Rajat Chhotelal Thorat | Maharashtra TV 24 | 2020-21 | |

| Ramdas Ganesh Ambhore | Yazaki India Pvt. Ltd. | 2020-21 | |

| Samrat Ashok Khobragade | Teleperformance Pvt. Ltd. | 2020-21 | |

| Shubham Sureshkumar Gupta | Suntronics Renewable Pvt. Ltd. | 2020-21 | |

| Swati Dnyaneshwar Kurhadkar | Dhoot Transmission Pvt. Ltd. | 2020-21 | |

| Vishal Vishnu Meshram | Hexaware Pvt. Ltd | 2020-21 | |

| Adarsh Dhanraj Meghare | Team Computers | 2019-20 | |

| Amiyo Ajay Majumdar | Dhoot Transmission Pvt. Ltd. | 2019-20 | |

| Anil Haripada Baidhya | SMS Envocare Limited | 2019-20 | |

| Ankit Ganesh Rahangdale | TATA Consultancy Services | 2019-20 | |

| Ankosh Vasanta Wankhade | Suntronics Renewable Pvt. LTd | 2019-20 | |

| Ashwajit Istari Hirekhan | Dhoot Transmission Pvt. Ltd. | 2019-20 | |

| Badal Bandu Nande | Suntronics Renewable Pvt. LTd | 2019-20 | |

| Bhushan Rahul Taksande | Team Computers | 2019-20 | |

| Dhanraj Prakash Shahu | Suntronics Renewable Pvt. LTd | 2019-20 | |

| Jotesh Singh | Dhoot Transmission Pvt. Ltd. | 2019-20 | |

| Kapil Pruthviraj Dandge | Suntronics Renewable Pvt. LTd | 2019-20 | |

| Kaushal Dhanraj Kurve | Suntronics Renewable Pvt. LTd | 2019-20 | |

| Mahesh Narayan Gadhave | LTI Pvt Lmtd | 2019-20 | |

| Mitesh Vishnuji Ikhar | Team Computers | 2019-20 | |

| Niklesh Kumar Shahu | Shubham Enterprises | 2019-20 | |

| Nitish Santosh Rahangdale | Dhoot Transmission Pvt. Ltd. | 2019-20 | |

| Onkar Laxman Jadhav | Suntronics Renewable Pvt. LTd | 2019-20 | |

| Parfull Ashok Nagpure | Suntronics Renewable Pvt. LTd | 2019-20 | |

| Prajwal Himmatrao Ingole | Suntronics Renewable Pvt. LTd | 2019-20 | |

| Ranjit Kanhaiya Ramteke | Dhoot Transmission Pvt. Ltd. | 2019-20 | |

| Ravishankar Suresh Bisen | Suntronics Renewable Pvt. LTd | 2019-20 | |

| Roshan Banduji Deshmukh | Dhoot Transmission Pvt. Ltd. | 2019-20 | |

| Shubham Digambar Khapekar | Suntronics Renewable Pvt. LTd | 2019-20 | |

| Shubham Nokhelal Gautam | Team Computers | 2019-20 | |

| Sumit Naresh Tembhurne | Suntronics Renewable Pvt. LTd | 2019-20 | |

| Suraj Sanjay Mendhe | Dhoot Transmission Pvt. Ltd. | 2019-20 | |

| Tanmay Asto Dolui | Suntronics Renewable Pvt. LTd | 2019-20 | |

| Vrunal Kushab Dodke | Dhoot Transmission Pvt. Ltd. | 2019-20 | |

| Ankit Bharat Raipure | Suntronics Renewable Pvt. LTd | 2019-20 | |

| Gaurav Tikar | Suntronics Renewable Pvt. LTd | 2019-20 | |

| Kunal Kishor Shrivastava | Suntronics Renewable Pvt. LTd | 2019-20 | |

| Nilesh Tukaramji Dhawale | Dhoot Transmission Pvt. Ltd. | 2019-20 | |

| Prachyut Ganpat Ashtankar | Dhoot Transmission Pvt. Ltd. | 2019-20 | |

| Pranay Naresh Kurzekar | OCW (Orange City Water) Pvt. Ltd. | 2019-20 | |

| Priyadarshan Vilas Bingule | Dhoot Transmission Pvt. Ltd. | 2019-20 | |

| Rahul Vivekanand Chamat | Suntronics Renewable Pvt. LTd | 2019-20 | |

| Rohit Vikas Naik | Dhoot Transmission Pvt. Ltd. | 2019-20 | |

| Sajan Siddharth Chauhan | Team Computers | 2019-20 | |

| Santosh Vasanta Naranje | Dhoot Transmission Pvt. Ltd. | 2019-20 | |

| Shubham Babarao Amnerkar | Ideal Energy Projects Ltd | 2019-20 | |

| Tameshwar Meghnath Sarwa | Dhoot Transmission Pvt. Ltd. | 2019-20 | |

| Abhijit Vijay Shinde | Suntronics Renewable Pvt. Ltd | 2018-19 | |

| Angesh Ratiram Neware | Dhoot Transmission Pvt. Ltd. | 2018-19 | |

| Apendra Singh | Tech Mahindra Limited | 2018-19 | |

| Ashutosh Jaiswal | Suntronics Renewable Pvt. Ltd | 2018-19 | |

| Avinash Kailas Mude | Dhoot Transmission Pvt. Ltd. | 2018-19 | |

| Aviraj Pradeep Yadav | Dhoot Transmission Pvt. Ltd. | 2018-19 | |

| Bhushan Arun Bhopaye | DCE Refrigeration Pvt. Lmtd. | 2018-19 | |

| Chandan Kumar | Suntronics Renewable Pvt. Ltd | 2018-19 | |

| Dhananjay Mahesh Pandey | Metro Global Solution Center | 2018-19 | |

| Hitesh Kewalram Nikhare | TNM Furnitech | 2018-19 | |

| Kishor Ramrao Tayde | Dhoot Transmission Pvt. Ltd. | 2018-19 | |

| Mayur Anilrao Dongre | Dhoot Transmission Pvt. Ltd. | 2018-19 | |

| Nikhil Kishorrao Wanmali | TATA private Limited | 2018-19 | |

| Prajwal Purushottam Ninawe | Byjus | 2018-19 | |

| Prashant Ramesh Pathak | Dhoot Transmission Pvt. Ltd. | 2018-19 | |

| Rohan Shekhar Satpute | Utkarsh small Finance Bank | 2018-19 | |

| Rohit Babulal Patle | Suntronics Renewable Pvt. Ltd | 2018-19 | |

| Rohit Nilkanth Satpute | Dhoot Transmission Pvt. Ltd. | 2018-19 | |

| Sahil Ramesh Fulzele | Suntronics Renewable Pvt. Ltd | 2018-19 | |

| Saurabh Rajiv Bardikar | Dhoot Transmission Pvt. Ltd. | 2018-19 | |

| Vaibhav Dnyaneshwar Karale | DCE Refrigeration Pvt. Lmtd. | 2018-19 | |

| Vrushabh Mohane | Dhoot Transmission Pvt. Ltd. | 2018-19 | |

| Aniket Ajay Umare | Dhoot Transmission Pvt. Ltd. | 2018-19 | |

| Avinash Anil Thakare | Dhoot Transmission Pvt. Ltd. | 2018-19 | |

| Dhananjay Keshorao Girhepunje | Suntronics Renewable Pvt. Ltd | 2018-19 | |

| Gajanan Vishvanath Jadhav | Suntronics Renewable Pvt. Ltd | 2018-19 | |

| Suyog Ramesh Ingle | Suntronics Renewable Pvt. Ltd | 2018-19 | |

| Vikas Shivram Wadhave | Teleperformance Pvt. Lmtd | 2018-19 |

Faculties and Students during the program

Prof. Shrutika Nitnaware offered memento to Student Mr. Tanay Singh

Dean Academic Dr. Radharaman Shaha offering memento to student Mr. Sagar Pohane

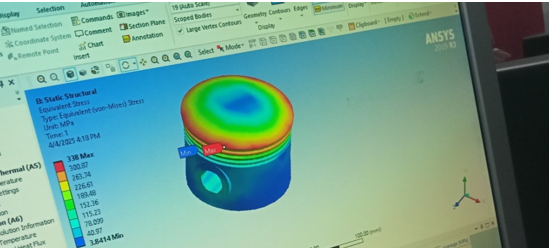

Two Days Hands on Training Ansys Workshop Group Photos of All Participants

Models created by students during the training (Piston)

Hands on Training on Electric Vehicle

Re-installation of forum body- 2024-25

Welcome of chief guest Mr. Ritesh Jain

Lecture delivery on Industry 4.0 by chief guest

10th International Conference in the Department of Mechanical and Aeronautical Engineering, Dr. Shard Chaudhary, Associate Professor and Dean (OBE) of YCC, Nagpur, delivered the keynote address, with Ritesh Bnapurkar, Dean of IQAC, serving as the session chair.

During the conference presentation, the judging panel, including Dr. Shard Chaudhary, Associate Professor and Dean (OBE) of YCC, Nagpur, and Ritesh Bnapurkar, Dean of IQAC, carefully evaluated each presentation.

Following the completion of presentations, a group photo was taken with the keynote speaker, session chair, and faculty members at the 10th International Conference in the Department of Mechanical and Aeronautical Engineering.

Expert deliver presentation to the students on Industry 4.0

Guest lecture on Industry 4.0 coordination team and expert at centre

Attention of students toward guest lecture and experts team

Students observe and understand working of calibration instruments

Attention of students toward guest lecture and experts team

Presentation of G-memento to Mr. Pramod Nichat

One week FDP on – “3D Printing and its Application in industry 4.0”

Expert Lecture on The essence of Industrial Robotics and Automation and Opportunities for Graduates by Mr. ANIL TATODE

Expert Lecture on Intellectual Property Right and Patent Information System by Mrs. Chhaya Satpute

Guest Lecture on the topics, of “Industry Expectations from Young Engineers by Mr. Manish K. Shahane

Industrial Visit at Br. SheshraoWankhedeShetkari Soot GirniLtd, Nagpur

Industrial Visit at Khosla Engineering Industries” Hingna, Nagpur

Industrial Visit at Lokmat Printing Press, Industrial Area Butibori

Parents Teacher Meet

| 2021-22 |

|---|

Felicitation of Faculty Members on Teachers day Celebration

Felicitation of Prof. Vidyadhar Kshirsagar

Felicitation of Prof. Vishwajeet Ambade

Felicitation of Prof .Praful Randive

Appreciation Certificate of Prof. Praful Randive

Appreciation Certificate of Dr. Vijay Talodhikar

| 2020-21 |

|---|

Felicitation of Dr.Vijay Talodhikar

Felicitation of Prof. Ritesh Banpurkar

Certificates of appreciations of Prof. Ravinndra Shende

Felicitation of Prof. Praful Randive

Felicitation of Prof. Niteen Kakde

Felicitation of Prof. Deepali Bhoyar

Felicitation of Dr. Prashant kadu

| Academic Year | No. of Participations within the state |

|---|---|

| 2022-23 | 29 |

| 2021-22 | 37 |

| 2020-21 | 8 |

| 2019-20 | 28 |

| No. of Participations within the state | |||||

|---|---|---|---|---|---|

| Sr. No. | Name of Student | Year | Name of Activity | Position/ Remark | Event Organized By |

1 |

Vishakha Butlekar |

2022-23 |

Teknodion 2023 |

First Position |

Kavikulguru Institute of Technology and Science, Ramtek |

2 |

Gaurav Thakre |

2022-23 |

Teknodion 2023 |

First Position |

Kavikulguru Institute of Technology and Science, Ramtek |

3 |

Saurabh Kittey |

2022-23 |

Teknodion 2023 |

First Position |

Kavikulguru Institute of Technology and Science, Ramtek |

4 |

Amol Jadhav |

2022-23 |

Teknodion 2023 |

First Position |

Kavikulguru Institute of Technology and Science, Ramtek |

5 |

Roshan Karokar |

2022-23 |

Techkrunch – 2023 |

Second Position |

G H Raisoni Institute of Engineering and Technology |

6 |

Praful Raut |

2022-23 |

Techkrunch – 2023 |

Second Position |

G H Raisoni Institute of Engineering and Technology |

7 |

Ankit Singh |

2022-23 |

Techkrunch – 2023 |

Participated |

G H Raisoni Institute of Engineering and Technology |

8 |

Moin Khan |

2022-23 |

Techkrunch – 2023 |

Participated |

G H Raisoni Institute of Engineering and Technology |

9 |

Mrunal Yeole |

2022-23 |

Techkrunch – 2023 |

Participated |

G H Raisoni Institute of Engineering and Te.chnology |

10 |

Vivek Deshmukh |

2022-23 |

Techkrunch – 2023 |

Participated |

G H Raisoni Institute of Engineering and Technology |

11 |

Atul Kumbhare |

2022-23 |

Techkrunch – 2023 |

Participated |

G H Raisoni Institute of Engineering and Technology |

12 |

Apurva Dongre |

2022-23 |

Techkrunch – 2023 |

Participated |

G H Raisoni Institute of Engineering and Technology |

13 |

Harsh Kardbhajne |

2022-23 |

Techkrunch – 2023 |

Participated |

G H Raisoni Institute of Engineering and Technology |

14 |

Sachin Talwekar |

2022-23 |

Techkrunch – 2023 |

Participated |

G H Raisoni Institute of Engineering and Technology |

15 |

Shubham Ghosikar |

2022-23 |

Techkrunch – 2023 |

Participated |

G H Raisoni Institute of Engineering and Technology |

16 |

Mahendra Mendhe |

2022-23 |

Techkrunch – 2023 |

Participated |

G H Raisoni Institute of Engineering and Technology |

17 |

Omprakash Dambhare |

2022-23 |

Techkrunch – 2023 |

Participated |

G H Raisoni Institute of Engineering and Technology |

18 |

Aditya Lakde |

2022-23 |

Techkrunch – 2023 |

Participated |

G H Raisoni Institute of Engineering and Technology |

19 |

Mayur Sonvane |

2022-23 |

Techkrunch – 2023 |

Participated |

G H Raisoni Institute of Engineering and Technology |

20 |

Suraj Surnar |

2022-23 |

Techkrunch – 2023 |

Participated |

G H Raisoni Institute of Engineering and Technology |

21 |

Kartik Lanjewar |

2022-23 |

Techkrunch – 2023 |

Participated |

G H Raisoni Institute of Engineering and Technology |

22 |

Jayendra Hajare |

2022-23 |

Techkrunch – 2023 |

Participated |

G H Raisoni Institute of Engineering and Technology |

23 |

Himanshu Madai |

2022-23 |

Techkrunch – 2023 |

Participated |

G H Raisoni Institute of Engineering and Technology |

24 |

Aman Tiwari |

2022-23 |

Techkrunch – 2023 |

Participated |

G H Raisoni Institute of Engineering and Technology |

25 |

Kaushik Bagade |

2022-23 |

Techkrunch – 2023 |

Participated |

G H Raisoni Institute of Engineering and Technology |

26 |

Anuj Bhaladhare |

2022-23 |

Techkrunch – 2023 |

Participated |

G H Raisoni Institute of Engineering and Technology |

27 |

Nikki Lilhare |

2022-23 |

Techkrunch – 2023 |

Participated |

G H Raisoni Institute of Engineering and Technology |

28 |

Aman Pachare |

2022-23 |

Techkrunch – 2023 |

Participated |

G H Raisoni Institute of Engineering and Technology |

29 |

Lankesh Selokar |

2022-23 |

Techkrunch – 2023 |

Participated |

G H Raisoni Institute of Engineering and Technology |

30 |

Aniket Sukhadeve |

2021-2022 |

Workshop |

Participated |

InfosisSpringboard |

31 |

Sushil Malghate |

2021-2022 |

National Intellectual Property Awareness Mission |

Participated |

Intellectual Property Office |

32 |

Mahesh Sawant |

2021-2022 |

Majhi Vasundhara Mitra |

Participated |

Government of Maharashtra ,Environment and climate change Department |

33 |

Suraj Sonarkar |

2021-2022 |

E Learning Program on VMC and CNC Programming |

Participated |

KEC Traning Center |

34 |

Himanshu Madai |

2021-2022 |

E Learning Program on VMC and CNC Programming |

Participated |

KEC Traning Center |

35 |

Avinash Khotele |

2021-2022 |

Blood Donation Camp |

Participated |

Jeevan Jyoti Blood Bank Nagpur |

36 |

Avinash Khotele |

2021-2022 |

Online Quize |

Participated |

B. L. Patil Polytechnic, Khopoli |

37 |

Dilip Lilhare |

2021-2022 |

Nirman 2020 Project Competition |

Participated |

KDK College of Engineering Nagpur |

38 |

Dilip Lilhare |

2021-2022 |

State Level Online Aptitude Test |

Participated |

Government Polytechnic, Jalna |

39 |

Mahesh Sawant |

2021-2022 |

Blood Donation Camp |

Participated |

Sainath BloodCentre, Nagpur |

40 |

Aman Tiwari |

2021-2022 |

Webinar Stability & Succes in Challenging Time |

Participated |

Tulsiramji Gaikwad-PatilCollege of Engineering in Association with IEI |

41 |

Sumit Verma, Shubham Maisgawali , Indrajit Verma , Pratik Jarile , Sanket Tohakar , Aditya Wghmare , Mithun Bagade |

2021-2022 |

Design and Fabrication of H-Type Vertical Hydraulic Press |

Published |

Journal of Fluid Mechanics and Mechanical Design |

42 |

Pramod Bhure , Sourabh Kinnake, Sushant Harinkhede |

2021-2022 |

Design And Fabrication Of Advance Solar Water Heater |

Published |

GIS Science Journal |

43 |

Lakhan Jadhav, Karan Ranait, Jayash Dhotkar, Mahendra Rahangdale, Sanket Bagade, Swapnil Madhavi |

2021-2022 |

Real-Time Monitoring of CO Emission in Vehicle Using Cognitive IOT with temperature and Alcohol Detector |

Published |

IJAITE |

44 |

Akshay Mankar, Rushali Dhande, Roshan Thote, Simran Wasnik, Sanket Kumar, Pradip Rane |

2021-2022 |

Ergonomic Design of CNC Machine for Disabled Operation |

Published |

International Journal of Advance Research and Innovative Ideas in Education |

45 |

Akash Bawankar, Priyanshu Wasnik, Makarand Charpe, Rohit Sangole, Sandip Sahare, Kartik Jaiswal |

2021-2022 |

Pest Controlling Robot for Detecting the Deficiencies in plant for proper fertillizer application |

Published |

International Journal of Advance in Engineering and Management (JIAEM) |

46 |

Pravin Chandewar, Avinash Khotele, Dharmendra Sonare, Avinash Hembade, Rushabh Meshram,Harshal Sontakke |

2021-2022 |

Design and Febrication of Stair Climbing Robot Rocker Bogie Mechanism |

Published |

International Journal of Advance Research and Innovative Ideas in Education |

47 |

Saurabh Kawale, Pradeep Harinkhede, Nilesh Thakare, Saroj Patle, Manish Dolas, |

2021-2022 |

Design and Febrication of Electromagnatik Braking System |

Published |

International Journal of Advance Research in Engineering and Science (IJRES) |

48 |

Bahudnyan Tamgade, Akshay Mujmule, Umesh Gajghate, Saurabh Wandare, Mujahid Sheikh, Vishal Paikrao |

2021-2022 |

Design and Febrication of Drill Jig for Flange Coupling |

Published |

International Journal of Research and Innovative Ideas in Education |

49 |

Pravin Chandewar, Avinash Khotele, Dharmendra Sonare, Avinash Hembade, Rushabh Meshram,Harshal Sontakke |

2021-2022 |

International Conference on Industrial Engineering and Management |

Published |

Manaviya National Institute of Technology MNIT Jaipur |

50 |

Rahul Bondre |

2021-2022 |

Design and Febrication of Win d Mill Turbine |

Published |

International Journal of Engineering and Technology and Science |

51 |

Mahesh Sawant, Jaspal Rathod,Rushikesh Hamane, Sajeshwari Bhagat, Sumit Bawankule, Kunal Adhau |

2021-22 |

Design and Fabrication of Stair Climbing Mechanism to lift load over Stair |

Published |

International Journal of Scientific Reasearch in Engineering and Management |

52 |

Mahesh Swant, Kunal Adhau, Rushikesh Hamane, Jaspal Rathod, Sajeshwari Bhagat, Sumit Bawankule |

2021-22 |

Design and Fabrication of Stair Climbing Mechanism lift load over Stair |

Published |

International Journal of Advance Research and Innovative Ideas in Education |

53 |

Rajesh Anparti |

2021-22 |

Design and Fabrication of Pedal Operated Grain Sieving Machine for Agriculture used |

Published |

International Journal of Modernization in Engineering Technology and Science |

54 |

Kushal Waghmare,Priyasanghapal Thool, Rajesh Anparti, Vivek Pullawar, Rahul Jane, Vijay Barange |

2021-22 |

Design and Fabrication of Pedal Operated Sieving Machine for Agriculture use |

Published |

International Journal of Advance Research and Innovative Ideas in Education |

55 |

Bankesh Sarkar, Bishwanath Chakravorty, Rahul Bondre ,Utkarsh Chafle, Sudip Joshi, Gaurav Dhandhare |

2021-22 |

Design and Fabrication Maglev Windmill Turbine |

Published |

International Journal of Engineering and Technology and Science |

56 |

Lokesh Bhagat, Nikhil Pardhi, Kamlesh Rahangdale, Harsh Pandey, Rushikesh Vasake, Pratik Katre |

2021-22 |

Design and Fabrication of Pesticides Spraying Drone for Agriculture |

Published |

International Journal of Advance Research and Innovative Ideas in Education |

57 |

Lokesh Bhagat, Nikhil Pardhi, Kamlesh Rahangdale, Harsh Pandey, Rushikesh Vasake, Pratik Katre |

2021-22 |

Design and Fabrication of Pesticides Spraying Drone for Agriculture |

Published |

International Journal of Engineering and Technology |

58 |

Arpit Ramteke, Hemant Meshram, Narendra Barihan, Nikhil Urkude, Sagar Porate, Shubham Chaware, |

2021--22 |

Design and Fabrication of Pneumatic Sheet Metal Cutting |

Published |

International Journal of Advance Research and Innovative Ideas in Education |

59 |

Akshay Bondre |

2021-22 |

Design and Fabrication of Regenerative Braking System |

Published |

International Journal of Research in Engineering and Science |

60 |

Sujit Varade, Sahil Pathan, Subham Pathe, Sagar Wahane, Shubham Sonwane, Umesh Nagale |

2021-22 |

Design and fabrication of a Solar Grass Cutter: A Review |

Published |

International Journal of Progressive Research in Engineering Management and Science |

61 |

Pravin Chandewar, Avinash Khotele, Dharmendra Sonare, Avinash Hembade, Rushabh Meshram,Harshal Sontakke |

2021-22 |

Design and Fabrication of Stair Climbing Robot Rocker Bogie Mechanism |

Published |

International Journal of Advance Research and Innovative Ideas in Education |

62 |

Ankit Gajbhiye, Shubham Mahakalkar, Sarang Shirbhayye, Pratik Dumare, Gaurav Sahu, Vijay Lade, Aniket Ande |

2021-22 |

Design and Fabrication of Mechanical Sand Filter |

Published |

International Journal of Advance Research and Innovative Ideas in Education |

63 |

Shailesh Shahu, Rahul Pandit, Devrao Kadam, Gaurav Pathode, Aniket Ramteke, Akash Bawane |

2020-21 |

Shoe Sanitization Machine |

Published |

International Journal of Innovative Research in science, Engineering and Technology. |

64 |

Shailesh Shahu, Rahul Pandit, Devrao Kadam, Gaurav Pathode, Aniket Ramteke, Akash Bawane |

2020-21 |

Shoe Sanitization Machine |

Published |

International Journal of Research in Engineering, Science and Management |

65 |

Tushar Shirpurkar, Sailesh Raut, Anup Mistry |

2020-21 |

Automated Drain Cleaning System under Swachh Bharat Abhiyan |

Published |

International Journal of Advances in Engineering and Management |

66 |

Ashish Hulke, Gopal Meshram, Vikarant moon, Prem Dome, Akshay Shrirame Prakash Kakade |

2020-21 |

Fabrication and Design of a Dual Side Shaping Machine for Industrial Applications |

Published |

International Journal of Innovative Research in science, Engineering and Technology. |

67 |

Ashwadeep Fulzele, Abhijeet Mishra, Prabhat Mandal |

2020-21 |

Design Calculations of Turmeric Polishing Machine |

Published |

International Journal of Research in Engineering, Science and Management |

68 |

Ajinkya Giri, Akshay Adalakondawar |

2020-21 |

Design and Optimization of Image Processing Drone |

Published |

International Research Journal of Engineering and Technology |

69 |

Pankaj Badhiye, Palash Balpande, Kaustubh Ghotkar |

2020-21 |

Design and Fabrication of Sheet Metal Cutting Machine by using Pneumatic Power |

Published |

International Research Journal of Engineering and Technology |

70 |

Gaurav Mall |

2019-20 |

ADHYAAN 2020, Technical Festival |

1st Position |

Government College of Engineering Nagpur |

71 |

Gaurav Tikar |

2019-20 |

ADHYAAN 2020, Technical Festival |

1st Position |

Government College of Engineering Nagpur |

72 |

Roshan Deshmukh |

2019-20 |

ADHYAAN 2020, Technical Festival |

1st Position |

Government College of Engineering Nagpur |

73 |

Ankit Rahangdale |

2019-20 |

ADHYAAN 2020, Technical Festival |

1st Position |

Government College of Engineering Nagpur |

74 |

Mahesh Gadhave |

2019-20 |

ADHYAAN 2020, Technical Festival |

1st Position |

Government College of Engineering Nagpur |

75 |

Akshay Turkar |

2019-20 |

ADHYAAN 2020, Technical Festival |

1st Position |

Government College of Engineering Nagpur |

76 |

Roshan Deshmukh |

2019-20 |

Hackathon 2.0 Paper Presentation |

Solar operated Pesticide Sprayer Rover Vehicle |

Mayur Innovation Council Mankapur Stadium |

77 |

Jyotesh Rathore |

2019-20 |

Hackathon 2.0 Paper Presentation |

Multirole Wheelchair |

Mayur Innovation Council Mankapur Stadium |

78 |

Mitesh Babarwal |

2019-20 |

Hackathon 2.0 Paper Presentation |

Multirole Wheelchair |

Mayur Innovation Council Mankapur Stadium |

79 |

Vishal Wayzode |

2019-20 |

Hackathon 2.0 Paper Presentation |

Multirole Wheelchair |

Mayur Innovation Council Mankapur Stadium |

80 |

GauravTikar |

2019-20 |

Hackathon 2.0 Paper Presentation |

Solar operated Pesticide Sprayer Rover Vehicle |

Mayur Innovation Council Mankapur Stadium |

81 |

Tanmay Dolui |

2019-20 |

Hackathon 2.0 Paper Presentation |

Multirole Wheelchair |

Mayur Innovation Council Mankapur Stadium |

82 |

Badal Nande |

2019-20 |

Hackathon 2.0 Paper Presentation |

Design and Fabrication of Multiporpose Mechanical Operation Machine |

Mayur Innovation Council Mankapur Stadium |

83 |

Kaushal Kurve |

2019-20 |

Hackathon 2.0 Paper Presentation |

Design and Fabrication of Multiporpose Mechanical Operation Machine |

Mayur Innovation Council Mankapur Stadium |

84 |

Alka Kapse |

2019-20 |

Hackathon 2.0 Paper Presentation |

Design and Fabrication of Multiporpose Mechanical Operation Machine |

Mayur Innovation Council Mankapur Stadium |

85 |

Niklesh Sahu |

2019-20 |

Hackathon 2.0 Paper Presentation |

Design and Fabrication of Multiporpose Mechanical Operation Machine |

Mayur Innovation Council Mankapur Stadium |

86 |

Sajan Chouhan |

2019-20 |

Hackathon 2.0 Paper Presentation |

Design and Fabrication of Multiporpose Mechanical Operation Machine |

Mayur Innovation Council Mankapur Stadium |

87 |

Nilesh Dhawale |

2019-20 |

Hackathon 2.0 Paper Presentation |

Design and Fabrication of Multiporpose Mechanical Operation Machine |

Mayur Innovation Council Mankapur Stadium |

88 |

Ashutosh Jaiswal |

2018-19 |

TECHNO-ARENA 2K19, A National Leven Technical Event |

Participated |

Government College of Engineering Kalahandi, Bhawanipatna, Odisha |

89 |

Rohit Patle |

2018-19 |

TECHNO-ARENA 2K19, A National Leven Technical Event |

Participated |

Government College of Engineering Kalahandi, Bhawanipatna, Odisha |

90 |

Hitesh Nikhare |

2018-19 |

TECHNO-ARENA 2K19, A National Leven Technical Event |

Participated |

Government College of Engineering Kalahandi, Bhawanipatna, Odisha |

91 |

Ashvini Bhanarkar |

2018-19 |

TECHNO-ARENA 2K19, A National Leven Technical Event |

Participated |

Government College of Engineering Kalahandi, Bhawanipatna, Odisha |

92 |

Ujwal Rewatkar |

2018-19 |

TECHNO-ARENA 2K19, A National Leven Technical Event |

Participated |

Government College of Engineering Kalahandi, Bhawanipatna, Odisha |

93 |

Prajwal Rewatkar |

2018-19 |

TECHNO-ARENA 2K19, A National Leven Technical Event |

Participated |

Government College of Engineering Kalahandi, Bhawanipatna, Odisha |

94 |

Prajwal Ninawe |

2018-19 |

TECHNO-ARENA 2K19, A National Leven Technical Event |

Participated |

Government College of Engineering Kalahandi, Bhawanipatna, Odisha |

95 |

Rohan Satpute |

2018-19 |

TECHNO-ARENA 2K19, A National Leven Technical Event |

Participated |

Government College of Engineering Kalahandi, Bhawanipatna, Odisha |

96 |

Nikhil Wanmali |

2018-19 |

TECHNO-ARENA 2K19, A National Leven Technical Event |

Participated |

Government College of Engineering Kalahandi, Bhawanipatna, Odisha |

97 |

Ashvini Bhanarkar |

2018-19 |

IGNITION Ignite Your Thoughts |

Participated |

Guru Nanak Institute of Technology, Nagpur |

98 |

Ujwal Rewatkar |

2018-19 |

IGNITION Ignite Your Thoughts |

Participated |

Guru Nanak Institute of Technology, Nagpur |

99 |

Prajwal Rewatkar |

2018-19 |

IGNITION Ignite Your Thoughts |

Participated |

Guru Nanak Institute of Technology, Nagpur |

100 |

Prajwal Ninawe |

2018-19 |

IGNITION Ignite Your Thoughts |

Participated |

Guru Nanak Institute of Technology, Nagpur |

101 |

Rohan Satpute |

2018-19 |

IGNITION Ignite Your Thoughts |

Participated |

Guru Nanak Institute of Technology, Nagpur |

102 |

Nikhil Wanmali |

2018-19 |

IGNITION Ignite Your Thoughts |

Participated |

Guru Nanak Institute of Technology, Nagpur |

103 |

Sanket Bhutange |

2018-19 |

ZENITH 2K18 Paper Presentation |

Participated |

G. H. Raisoni College of Engineering, Nagpur |

104 |

Vaibha Meshram |

2018-19 |

ZENITH 2K18 Paper Presentation |

Participated |

G. H. Raisoni College of Engineering, Nagpur |

105 |

Suraj Dabhade |

2018-19 |

ZENITH 2K18 Paper Presentation |

Participated |

G. H. Raisoni College of Engineering, Nagpur |

106 |

Rushabh Banarase |

2018-19 |

ZENITH 2K18 Paper Presentation |

Participated |

G. H. Raisoni College of Engineering, Nagpur |

107 |

Akash Tiwari |

2018-19 |

ZENITH 2K18 Paper Presentation |

Participated |

G. H. Raisoni College of Engineering, Nagpur |

108 |

Akshay Gadage |

2018-19 |

Hackathon Paper Presentation |

Innovation Idea for Sustainable development |

Mayur Innovation Council Mankapur Stadium |

109 |

Akash Dhude |

2018-19 |

Hackathon Paper Presentation |

Innovation Idea for Sustainable development |

Mayur Innovation Council Mankapur Stadium |

110 |

Bhushan Ujwane |

2018-19 |

Hackathon Paper Presentation |

Innovation Idea for Sustainable development |

Mayur Innovation Council Mankapur Stadium |

111 |

Bhumesh Kumar Sahare |

2018-19 |

Hackathon Paper Presentation |

Innovation Idea for Sustainable development |

Mayur Innovation Council Mankapur Stadium |

112 |

Chandrakant Ghugul |

2018-19 |

Hackathon Paper Presentation |

Innovation Idea for Sustainable development |

Mayur Innovation Council Mankapur Stadium |

113 |

Prakash Choudhari |

2018-19 |

TECH-NIRMITI 2019, National Level Technical Event, Paper Presentation |

Participated |

Abha Gaikwad-Patil College of Engineering, Nagpur |

114 |

Prashant Poddar |

2018-19 |

TECH-NIRMITI 2019, National Level Technical Event, Paper Presentation |

Participated |

Abha Gaikwad-Patil College of Engineering, Nagpur |

115 |

Shailendra Lichade |

2018-19 |

TECH-NIRMITI 2019, National Level Technical Event, Paper Presentation |

Participated |

Abha Gaikwad-Patil College of Engineering, Nagpur |

116 |

Rohit Satpute |

2018-19 |

TECH-NIRMITI 2019, National Level Technical Event, Paper Presentation |

Participated |

Abha Gaikwad-Patil College of Engineering, Nagpur |

117 |

Pranit Kumar Pathade |

2018-19 |

TECH-NIRMITI 2019, National Level Technical Event, Paper Presentation |

Participated |

Abha Gaikwad-Patil College of Engineering, Nagpur |

118 |

Shubham Deshmukh |

2018-19 |

TECH-NIRMITI 2019, National Level Technical Event, Paper Presentation |

Participated |

Abha Gaikwad-Patil College of Engineering, Nagpur |

119 |

Sanket Bhutange |

2018-19 |

TECH-NIRMITI 2019, National Level Technical Event, Paper Presentation |

Participated |

Abha Gaikwad-Patil College of Engineering, Nagpur |

120 |

Vaibhav Meshram |

2018-19 |

TECH-NIRMITI 2019, National Level Technical Event, Paper Presentation |

Participated |

Abha Gaikwad-Patil College of Engineering, Nagpur |

121 |

Suraj Dabhade |

2018-19 |

TECH-NIRMITI 2019, National Level Technical Event, Paper Presentation |

Participated |

Abha Gaikwad-Patil College of Engineering, Nagpur |

122 |

Rushabh Banarase |

2018-19 |

TECH-NIRMITI 2019, National Level Technical Event, Paper Presentation |

Participated |

Abha Gaikwad-Patil College of Engineering, Nagpur |

123 |

Akshay Tiwari |

2018-19 |

TECH-NIRMITI 2019, National Level Technical Event, Paper Presentation |

Participated |

Abha Gaikwad-Patil College of Engineering, Nagpur |

124 |

Vaibhav Karale |

2018-19 |

TECH-NIRMITI 2019, National Level Technical Event, Paper Presentation |

Participated |

Abha Gaikwad-Patil College of Engineering, Nagpur |

125 |

Suraj Gaidhane |

2018-19 |

TECH-NIRMITI 2019, National Level Technical Event, Paper Presentation |

Participated |

Abha Gaikwad-Patil College of Engineering, Nagpur |

126 |

Sahil Fulzele |

2018-19 |

International Conference on Green Energy for Sustainable Development |

Designing floating structure for solar plant |

Government Polytechnic, Nagpur |

127 |

Chandrakant Ghugul |

2018-19 |

International Conference on Green Energy for Sustainable Development |

Designing floating structure for solar plant |

Government Polytechnic, Nagpur |

128 |

Bhumesh Kumar Sahare |

2018-19 |

International Conference on Green Energy for Sustainable Development |

Designing floating structure for solar plant |

Government Polytechnic, Nagpur |

129 |

Bhushan Ujwane |

2018-19 |

International Conference on Green Energy for Sustainable Development |

Designing floating structure for solar plant |

Government Polytechnic, Nagpur |

130 |

Akshay Gadage |

2018-19 |

International Conference on Green Energy for Sustainable Development |

Designing floating structure for solar plant |

Government Polytechnic, Nagpur |

131 |

Rohit Satpute |

2018-19 |

International Conference on Green Energy for Sustainable Development |

Determination of Suitability of Adhesive for Bamboo |

Government Polytechnic, Nagpur |

132 |

Prashant Poddar |

2018-19 |

International Conference on Green Energy for Sustainable Development |

Determination of Suitability of Adhesive for Bamboo |

Government Polytechnic, Nagpur |

133 |

Shailendra Lichade |

2018-19 |

International Conference on Green Energy for Sustainable Development |

Determination of Suitability of Adhesive for Bamboo |

Government Polytechnic, Nagpur |

134 |

Pranitkumar Pathede |

2018-19 |

International Conference on Green Energy for Sustainable Development |

Determination of Suitability of Adhesive for Bamboo |

Government Polytechnic, Nagpur |

135 |

Prakash Choudhari |

2018-19 |

International Conference on Green Energy for Sustainable Development |

Determination of Suitability of Adhesive for Bamboo |

Government Polytechnic, Nagpur |

136 |

Shubham Deshmukh |

2018-19 |

International Conference on Green Energy for Sustainable Development |

Determination of Suitability of Adhesive for Bamboo |

Government Polytechnic, Nagpur |

137 |

Gaurav Patle |

2018-19 |

National Conference on Recent Advance in Engineering and Technology |

Automatic Punching Machine |

Government College of Engineering Nagpur |

138 |

Gopal Pandey |

2018-19 |

National Conference on Recent Advance in Engineering and Technology |

Automatic Punching Machine |

Government College of Engineering Nagpur |

139 |

Anilkumar Chouhan |

2018-19 |

National Conference on Recent Advance in Engineering and Technology |

Automatic Punching Machine |

Government College of Engineering Nagpur |

140 |

Apendra Singh |

2018-19 |

National Conference on Recent Advance in Engineering and Technology |

Automatic Punching Machine |

Government College of Engineering Nagpur |

141 |

Hiteh Nikhare |

2018-19 |

National Conference on Recent Advance in Engineering and Technology |

Automatic Punching Machine |

Government College of Engineering Nagpur |

142 |

Rohit Patle |

2018-19 |

National Conference on Recent Advance in Engineering and Technology |

Intelligent Robert walking assistant of elder and handicapped people |

Government College of Engineering Nagpur |

143 |

Ashutosh Jaiswal |

2018-19 |

National Conference on Recent Advance in Engineering and Technology |

Intelligent Robert walking assistant of elder and handicapped people |

Government College of Engineering Nagpur |

144 |

Satish Mandawe |

2018-19 |

National Conference on Recent Advance in Engineering and Technology |

Improving Efficiency of IC Engine |

Government College of Engineering Nagpur |

145 |

Avinash Thakare |

2018-19 |

National Conference on Recent Advance in Engineering and Technology |

Improving Efficiency of IC Engine |

Government College of Engineering Nagpur |

146 |

Aniket Umare |

2018-19 |

National Conference on Recent Advance in Engineering and Technology |

Improving Efficiency of IC Engine |

Government College of Engineering Nagpur |

147 |

Mukesh Ale |

2018-19 |

National Conference on Recent Advance in Engineering and Technology |

Improving Efficiency of IC Engine |

Government College of Engineering Nagpur |

148 |

Chandan Kumar Singh |

2018-19 |

National Conference on Recent Advance in Engineering and Technology |

Improving Efficiency of IC Engine |

Government College of Engineering Nagpur |

149 |

Chandan Kumar Singh |

2018-19 |

International Conference on Techtrends in Science & Engineering |

Participated |

Suryodaya College of Engineering |

150 |

Shankar Ghule |

2018-19 |

International Conference on Techtrends in Science & Engineering |

Participated |

Suryodaya College of Engineering |

151 |

Kishor Tayade |

2018-19 |

International Conference on Techtrends in Science & Engineering |

Participated |

Suryodaya College of Engineering |

152 |

Prashant Pathak |

2018-19 |

International Conference on Techtrends in Science & Engineering |

Participated |

Suryodaya College of Engineering |

| Project title | Funded By | Internal Revenue Generated (Rupees) | Duration | Year | Status of the Project |

|---|---|---|---|---|---|

| CNC Training | KEC International Nagpur | 6000 | 2 days | 2022-23 | completed |

| Capacity Building Program | Ambuja Cement Foundation, Mumbai | 485100 | 36 days | 2019-20 | completed |

| CNC Training | KEC International Nagpur | 57000 | 3 days | 2019-20 | completed |